FABTEK Comprehensive Capabilities

At FABTEK, our capabilities extend beyond manufacturing. With state-of-the-art facilities and a dedicated team of experts, we offer a comprehensive range of services, including precision engineering, custom fabrication, rapid prototyping, and quality assurance. From concept to delivery, we are committed to meeting the unique needs of our clients across various industries, ensuring excellence in every product we produce.

- MACHINE AND PART MAKING

The machine work shop is equipped with a diverse range of plant and equipment.

Punch press tooling can be produced to meet specific requirements.

Due to the diversified plant and equipment in our factory , a comprehensive range of manufacturing solutions are available to meet our customers requirements.

Machine List

- 1 x 2024 Amada VN3015AJe (VENTIS model) 6000W laser cutting machine

- 1 x 2022 Amada ENSIS3015AJ 6000W laser cutting machine

- 1 x 2016 Amada LCG 3015 AJ2000W Fiber/Laser CNC operated cutting machine with OVS positioning system

- 1 x 2019 Amada LC2515C1AJ3000 CNC operate Punch and Fiber/Laser Combination machine

- 1 x 2024 Amada EM-ZR Series CNC operated punching machine

- 1 x 2016 Amada EM-ZR Series CNC operated punching machine

- 1 x 2024 JQL Tube/Profile Laser Cutting Model : FLT7020H1 6KW

- 2 x 2019 Amada EG series CNC press Break machine 40Ton/1M

- 2 x 2024 Amada EGB8025E CNC Press Break 80 Ton/2.5M

- 2 x 2016 Amada HG series CNC Press Break machine 130Ton/3M

- 1 x 2016 Amada HG series CNC Press Break machine 240Ton/4M

- 1 x 2011 Amada NC press break 1 x 125T/3M

- 1 x 2019 Amada GUNMAN1002 CNC Stud Welder

- 2 x 2018/2023 PEMSERTER® Series 4® stud press

- 1 x 2019 Amada HFA400W BANDSAW MACHINE

- 1 x 2012 Okuma Genosi 250 CNC Lathe

- 1 x 2018 DMG Mori CNC Lathe CLX-450

- 1 x 2018 DMG Mori CNC Milling CMX-800V

- 2 x 2011 Manually operated lathe

- 4 x 2011/2018 Punch & Press

- 1 x 2011 CNC operated wire cutting

- 1 x 2023 Laser Engraving machine 50W

- 2 x 2003/2011 NC operated mandrel tube bending

- 1 x 2018 ABB Robotic Welding Station

- 1 x 2023 Flange rotation welding jig

- 1 x Welding Rotation Jig

ASSEMBLY

Assembly and welding areas are set up so that production work cells can be easily adjusted to suit products being manufactured at the time.

For low volume orders work cells are equipped with manually operated LASER, MIG, TIG, ARC welding, and Oxy/Acetylene brazing capabilities.

For high-volume production orders, FabTek has robotic welding stations with the capacity to weld steel, stainless steel, and aluminum products with maximum efficiency.

For specific and specialised products that our customers require, we apply ISO welding procedures, ISO 15609-1, ISO15614-1. In addition FABTEK welders are qualified with welding standard ISO 9606-1 to complete such products.

PROJECTS AREA

During 2016 Fabtek extended our Factory by approx. 5,300M2 with the main intention to develop a project assembly department so we can offer our customers the additional capabilities of undertaking the full assembly of the parts we manufacture within our production facility and also the Mechanical, Electrical and Electronic installations .

During this time Fabtek has worked in very close co-operation with our customers developing new innovative assembled products such as:

-Roast Runner : Commercial Chicken Oven

-Dough Runner : Commercial Pocket Bread Oven

-Wayo : Battery powered Mobile Digital Signage

-Axis Dyno : Dynamometer for stationary road testing for motorcycles

We look forward to the opportunity to further expand our project assembly range of products with new and existing customers.

FINISHES

Fabtek has In house powder coating and wet spray coating facilities. Only the highest quality powder is used (www.tiger-coatings.com).

Testing is undertaken regularly to ensure the quality of the finish is maintained. Tests include:

•Appearance

•Color

•Hardness

•Gloss

•Adhesion

•Gravelometer

•Salt spray

We also offer Hot dipped galvanized , Electro Zinc Plating and E coating through out-sourcing to qualified local companies.

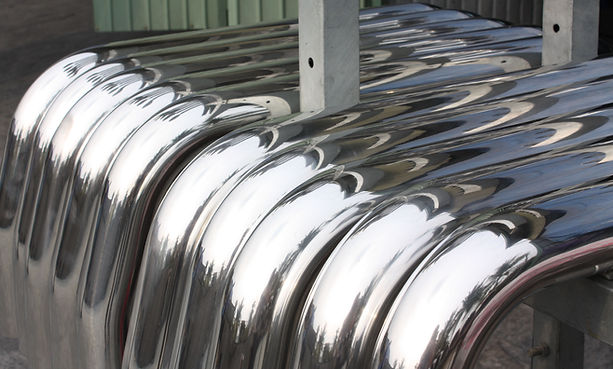

Fabtek has in house polishing facilities to achieve a high quality finish on stainless steel and aluminium products.

PACKING & SHIPPING

A wide range of labelling and packaging options are available eg: customer specific labels, labelled cardboard boxes, vacuum packaging and shrink wrapping. Honeycomb Cardboard shipping crates and pallets are produced to suit loose cargo and containerized shipping.

Complete delivery service available depending on customers requirements. Shipments can be arranged via air freight, loose cargo loads or container shipments. Shipments can be arranged to any air or sea port in the world.

QUALITY CONTROL

FABTEK is certified to ISO 9001:2015 and has based the QMS on consistently providing products and services that meet with customer expectations and regulatory requirements.

FABTEK Quality Management System complies with applicable requirements contained in ISO 9001:2015 , covers the design and provision of all company products, and encompasses all operations at the facility in Vietnam.

Regular internal audits on the QMS and annual external audits are performed by qualified QMS auditors.

DESIGN, RESEARCH AND DEVELOPMENT

Dedicated design, research and development department who provide customers with detailed drawings for their review and approval prior to production of their products.

A comprehensive 3D design is developed for customer approval before each product is manufactured. During production step by step process drawings are prepared and a detailed history of revisions is kept and these are all available for clients to keep for their records.

If required detailed PPAP submissions can be prepared allowing customers to clearly understand the manufacturing process and make constructive suggestions for improvement.